Research

Flotation: A paradigm of an industrial process requiring scientific knowledge from different disciplines and at several size scales

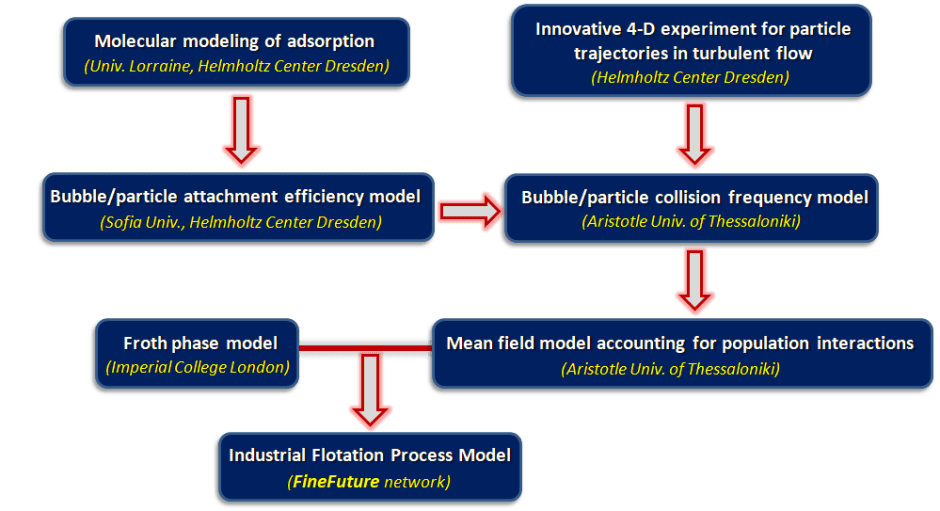

Flotation is a process of separation and concentration of suspended solid materials in liquids by exploiting the differences in the physicochemical properties of interfaces. It includes sub-processes such as adsorption at solid-liquid and gas-liquid interface, coagulation of solid particles, thin liquid film destabilization, particle-bubbles collision, bubble coalescence and breakage, three phase flow, turbulence creation etc. Obviously, a multidisciplinary approach is needed for its study with the chemists at one edge and fluid mechanics scientists at the other. Europe’s industry has a leading role in the manufacturing of mining equipment and technologies for metallurgical processing. The development of technologies that can efficiently separate very fine particles are indeed required for the valorisation of multiple minerals. Unfortunately, such break-through technologies have not yet been developed due to lack of fundamental understanding of the underlying physical phenomena. To overcome the aforementioned problems, a joint effort of Europe’s leading institutions from the private and public sector is made through the newly established FineFuture consortium (https://finefuture-h2020.eu). The FineFuture partners are convinced by their experience, expertise, and stakeholder knowledge that flotation, will remain the key technology for mineral particle processing. Yet, flotation needs to be entirely reengineered for the separation of very fine particles. In this respect, a new unified mathematical model of flotation, covering all the size scales from the molecular scale to the device scale is developed. A combination of co-current and sequential multiscale approaches is invoked. In particular, the pulp and froth physical domains are treated in parallel. Each of the two domains is treated through sequential multiscale approach. The adsorption process is simulated through molecular modelling and the bubble/particle attachment efficiency through thin film stability analysis. The above submodels are integrated to a bubble-particle collision frequency model taking into account the gravitational forces and the fine structure of the turbulence flow field. The resulting expressions are incorporated to a population balance model which will be the heart of the multiphase computational fluid dynamics code that will be used to simulate the actual flotation devices. It is believed that this approach will promote essentially both the scientific knowledge and the technology innovation and will set Europe as the world leader in flotation process.

Margaritis Kostoglou

Aristotle University of Thessaloniki, Department of Chemistry, Greece

How chemistry is helping in the fight against Coronavirus

Chemistry, like many other sectors, has been hit hard by falling demand and an uncertain future; however, and thanks to the efforts of many, it is playing a key role in this global fight against the disease. Many chemists have shown great commitment and flexibility in this difficult time. Some have reinvented themselves to quickly develop the much-needed quick tests for the detection of the virus. For example, a group of scientists from the University of Maryland School of Medicine (U.S.) has developed an experimental diagnostic test for COVID-19 that can visually detect the presence of the virus in just 10 minutes. Chemists are also playing a major role in the race for a new vaccine and have delivered some promising alternatives in a matter of few months (see Figure 1). For example, the vaccine candidate originally developed to target MERS, and now adapted by a team of Oxford University researchers, has already entered in phase II/III human’s trials. These, and many other examples, speak volumes of the commitment and adaptability of chemists to contribute when their help is most needed.

I also want to highlight the efforts of Chemistry educators who adapted their courses on the spot to teach remotely, learning, and incorporating new tools to being able to communicate, respond, and examine their students. Nothing of this, including balancing our professional and personal lives, has been easy, but there are important lessons for all in what the future of Chemistry education will look like in the post-COVID-19 time.

The chemical industry has had to reinvent itself without notice to produce the disinfectants, soaps, cleaning products, and the personal protective equipment that are having a key role in the control of the spread of the disease. In a time when supply chains are simply broken, many chemical plants have been reconverted to produce those chemicals we so desperately need. For example, BASF’s plant in Tarragona (Spain) has adapted to produce three million tons of hand sanitizer that are being donated to local hospitals. Similarly, Dow Chemical Company has been producing 300 tons of hand sanitizer per month in Stade (Germany), and has repurposed an existing facility in the U.S. to increase its production of this critical product. The new normal that will follow COVID-19 is going to demand profound changes in the chemicals industry to respond and in a more agile and effective way to the rapidly changing needs of volatile and uncertain time. Part of this effort should involve the digitalization of all its processes – from the plant to the office – and the diversification of its supply chains to ensure production and adapt to a rapidly changing demand.

At IUPAC, we have contributed to showcasing how chemistry is contributing to the fight against COVID-19 in a collaboration with the International Younger Chemists Network (IYCN) and the European Young Chemists’ Network (EYCN) through a series of webinars (see Figure 2). I want to take this opportunity to congratulate these young chemists for their leadership and for proving great examples of how Chemistry is key to solving the great problems of our time.

Javier García Martínez

President-Elect of the International Union of Pure and Applied Chemistry (IUPAC)

Director of the Molecular Nanotechnology Lab and Professor of Inorganic Chemistry at the University of Alicante, Spain

Sources:

Maryland test: https://www.umaryland.edu/news/archived-news/may-2020/covid-19-results-in-10-minutes-umb-studies-rapid-test.php

Oxford vaccine: http://www.ox.ac.uk/news/2020-05-22-oxford-covid-19-vaccine-begin-phase-iiiii-human-trials

BASF donation: https://www.basf.com/es/es/media/Noticias/Noticias2020/basf-tarragona-tambien-adapta-su-produccion-para-fabricar-gel-de.html

DOW donation: https://corporate.dow.com/en-us/news/press-releases/dow-commits–3-million-to-aid-covid-19-relief-efforts-and-adjust.html

IUPAC/IYCN/EYCN webinars: https://www.youtube.com/watch?v=xzpX7qeB8Vg

You must be logged in to post a comment.